Always on, ever reliable nuclear power represents THE existential threat to chaotically intermittent wind and solar. And those profiting from the greatest economic and environmental fraud of all time, know it and fear it. Hence the uptick in hysterical propaganda being fed to and through the MSM about the cost, dangers, risks and blah, blah, blah about nuclear power.

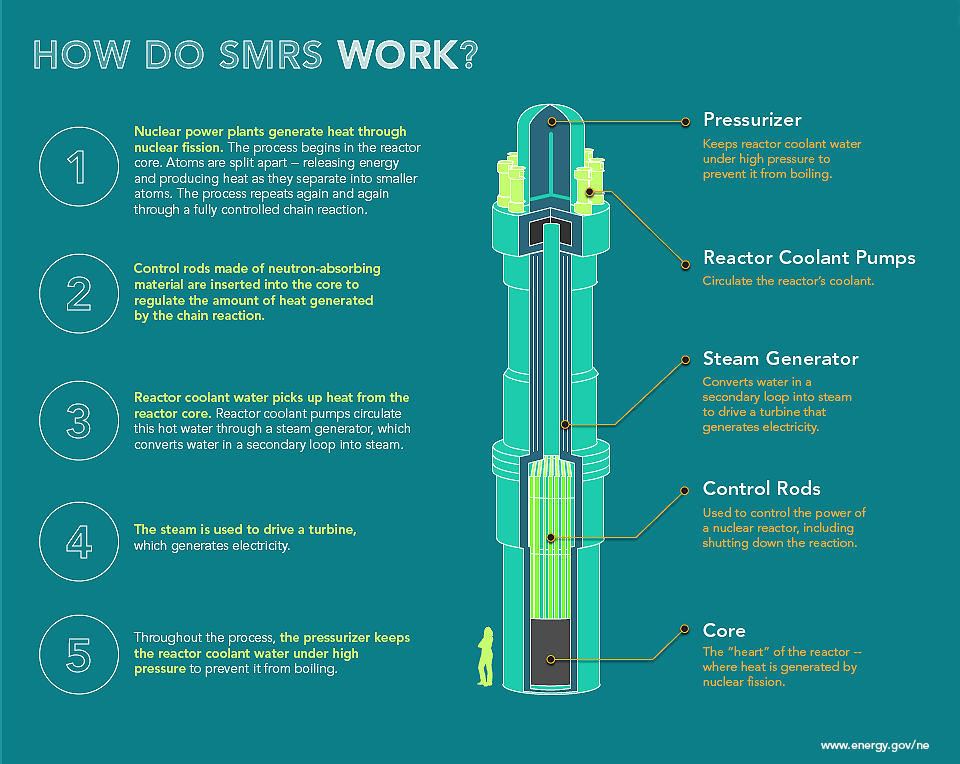

Trouble for the wind and solar cult is that they can never deliver on time and under budget. And they can never, ever compete the generation sources that operate around-the-clock, whatever the weather. Which explains their open hostility to nuclear power plants of any shape and size. Including Small Modular Reactors (SMRs).

Listen to the wind and sun cult and you’d think that Small Modular Nuclear Reactors are a work of far-fetched Science Fiction. The reality is that some 200 small nuclear reactors are presently powering 160 ships and submarines all around the world, and have been for decades.

The Brits evidently understand the obvious benefits of SMRs, with Rolls-Royce lining up to perfect their manufacturing techniques with help from Sheffield University, as this piece from Matt Oliver outlines below.

Rolls-Royce signs £15m deal to test mini-nuclear reactors in Sheffield

The Telegraph

Matt Oliver

20 May 2024

Rolls-Royce has signed a £15m deal with Sheffield University to trial manufacturing techniques for small modular reactors (SMRs), in the latest step towards making cheap nuclear power a reality.

Under the agreement, the engineering giant will make the first working prototypes of SMR modules at the university’s Advanced Manufacturing Research Centre.

It will then seek to work out efficient and repeatable processes that will let the company produce them in large numbers.

The investment was welcomed by Claire Coutinho, the Energy Secretary, who said: “Small Modular Reactors are the future of nuclear technology, and key to quadrupling the UK’s nuclear capacity by 2050 as part of the biggest expansion in 70 years.

“This multi-million-pound SMR manufacturing facility will be fantastic for Sheffield – making the Steel City once again the home to world-leading industry.”

SMRs will be assembled from hundreds of factory-made modules, which will be transported to sites and then put together “like Lego bricks”.

The initial phase of the Sheffield University deal will see Rolls spend £2.7m on producing three prototype modules by the end of this year.

If that work is successful, the company will spend more than £15m making prototypes of each of the 15 types of modules that will be needed throughout a finished SMR.

Victoria Scott, chief manufacturing engineering at Rolls-Royce SMR, said: “Our investment in setting up this facility and building prototype modules is another significant milestone for our business.”

Professor Koen Lamberts, president and vice-chancellor of the University of Sheffield, said: “We are very proud that Rolls-Royce SMR has chosen to base its module development facility at our Advanced Manufacturing Research Centre.”

Oliver Coppard, South Yorkshire’s mayor, said: “This announcement cements South Yorkshire’s position as the leading place to build small modular reactors, a cutting-edge technology which will be a key part of the global transition to clean energy.”

SMRs are seen as potential game-changers for the nuclear industry because of their modular construction.

In theory, this means they should be quicker to build than traditional, large-scale nuclear power plants and significantly cheaper as well – providing efficiency throughout production at scale.

Rolls has previously said each SMR should cost about £2bn and will generate about 470 megawatts (MW) of electricity.

For comparison, Hinkley Point C is currently forecast to cost as much as £35bn and will deliver 3.3 gigawatts of power.

On current budgets and forecasts, it suggests every 100MWs of power generated by an SMR would be delivered at less than half the cost of equivalent power coming from Hinkley.

However, the technology remains untested, with no SMRs in operation anywhere in the world. [Except for hundreds in ships and subs sailing all around the World]

The trial of manufacturing techniques in Sheffield comes as Rolls weighs up potential locations for a future factory that will make SMR modules.

It had drawn up a shortlist of locations that includes the International Advanced Manufacturing Park on the outskirts of Sunderland, Teesworks in Redcar and the Gateway industrial park in Deeside, Wales.

Originally, the company had also intended to build a heavy pressure vessels factory as well, which would supply another crucial part for its SMRs.

But the Telegraph revealed last month that this plan had now been scrapped, owing to delays in a UK government SMR design competition.

The competition – first announced by the Government in 2015 – has been repeatedly pushed back, with the winners now not expected to be revealed until summer at the earliest.

It means Rolls will now buy the heavy pressure vessels for its SMRs from a third-party supplier.

The company has also not ruled out reviving its plan for a heavy pressure vessel factory at some point in the future, if it builds up a healthy pipeline of orders.

The Telegraph

Shipyards, especially in South Korea, perfected the modular construction method decades ago. A shipyard would be the obvious place to build reactors of any size. Except they don’t want to touch them with a ten foot Pole (or two five-foot Ethiopians), because of the regulators sticking their nose into everything every step, gumming up the works, and increasing costs. If the regulators would instead say “We’ll inspect and test it after you build it, and then decide whether to put it into service,” they might (maybe) build them.