If ‘green’ means squandering the world’s resources, then wind and solar fit the bill, but if it’s about ‘saving the planet’, then they’re an almighty fraud.

Having operated in this space since December 2012, when it comes to wind and solar industry spin and propaganda, STT has seen it all and heard it all.

Wind and solar are always pitched up as ‘clean’ and ‘green’, with never a nod to what goes in to making a turbine or solar panel and a ‘quick, hey look over there’ response when anyone rumbles them on just how filthy and environmentally destructive their so-called ‘industries’ are.

All care and no responsibility is just how they like it. However, slowly but surely, people are waking up to the true environmental cost attached to the unreliables.

Jens Glüsing, Simon Hage, Alexander Jung, Nils Klawitter und Stefan Schultz take a look at the true costs of climate virtue signalling.

The Dirty Truth About Clean Technologies

Spiegel International

Jens Glüsing, Simon Hage, Alexander Jung, Nils Klawitter und Stefan Schultz

4 November 2021

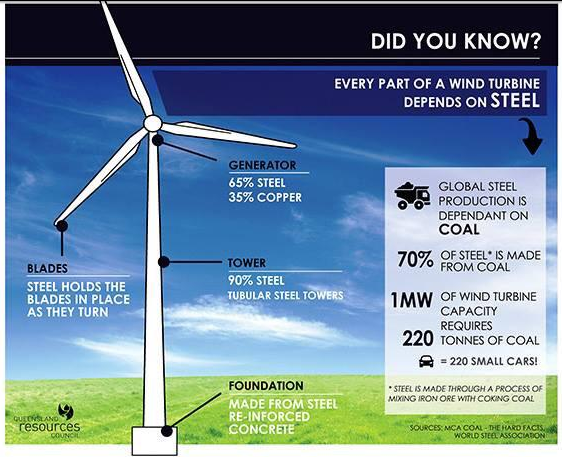

There’s a dirty secret hidden in every wind turbine. They may convert moving air cleanly and efficiently into electricity, but few know much about what they are made of. Much of the material inside wind turbines are the product of brutal encroachments on our natural world.

Each unit requires cement, sand, steel, zinc and aluminum. And tons of copper: for the generator, for the gearbox, for the transformer station and for the endless strands of cable. Around 67 tons of copper can be found in a medium-sized offshore turbine. To extract this amount of copper, miners have to move almost 50,000 tons of earth and rock, around five times the weight of the Eiffel Tower. The ore is shredded, ground, watered and leached. The bottom line: a lot of nature destroyed for a little bit of green power.

A visit to the Los Pelambres mine in northern Chile provides a clear grasp of the dimensions involved. It is home to one of the world’s largest copper deposits, a giant gray crater at an altitude of 3,600 meters (11,800 feet). The earth here is full of metalliferous ore. Just under 2 percent of the world’s copper production comes from this single pit.

Dump trucks, 3,500-horsepower strong, transport multi-ton loads down the terrace roads that line the mine. The boulders are transported by conveyor belt almost 13 kilometers (8 miles) into the valley, where the copper is extracted from the rock. This processing requires huge amounts of electricity and water, a particularly precious commodity in this arid region.

The project is operated by Antofagasta, a London-based Chilean mining corporation that owns 60 percent of the mine. The company built a hydroelectric plant in 2013, almost exclusively to supply electricity to Los Pelambres. Farmers protested against it, and have blamed the project for water shortages in the region.

Now, though, the mine is slated to grow even larger. The company is pumping additional volumes of desalinated seawater from the Pacific coast across the country. Company executives hope this will enable them to continue operating the mine for a few more years. Global demand for copper, after all, is expected to grow immensely, for power cables and electric motors. And for wind turbines.

There are great hopes that the green technology can be used to help save the climate, but that rescue also entails stripping the planet of precious resources. And this is the paradox behind what is currently the most important project of the industrialized world: the global energy transition. The dilemma, which is becoming increasingly apparent, is also on the minds of the 25,000 or so delegates at the World Climate Conference currently taking place in Glasgow. Deposits in the poor South are being exploited so that the rich North can transition to environmental sustainability. At least to a lifestyle that appears sustainable. Mathis Wackernagel, a resource researcher who lives in California, describes it as a disastrous development. “We haven’t quite thought the future through,” he says.

Wackernagel, who was born in Basel, Switzerland, in 1962, is one of the most influential figures in the environmental movement. He coined two metaphors that have influenced thinking about sustainability around the world.

One is the idea of the environmental footprint, which indicates how much land and sea area is needed to renew the resources that we have consumed. According to Wackernagel’s calculations, 1.75 Earths would be needed for the planet to regenerate itself. If all the people on the planet were to behave as wastefully as the inhabitants of Germany, it would require almost three Earths.

The other is Earth Overshoot Day, which marks the day each year on which humanity has used as many resources as the planet can replenish in a year. This year, that day fell on July 29. The two metaphors serve to underscore Wackernagel’s main point: “We are using resources of the future to pay for the present.”

He’s referring to the daily consumption of around 90 million barrels of crude oil, the use of land for buildings, roads or arable land – and also the exploitation of mineral resources. Wackernagel says the biological budget is limited and that humans must decide what they want to use it for. If we use it to mine copper, then it won’t, for example, be available for the cultivation of beets. He says it’s too short-sighted to think that all we have to do to protect the environment is to recreate the fossil-fueled world with electricity and swap the six-cylinder Jaguar for the battery-powered Tesla.

Few are aware of this fact as they drive their electric vehicle, use electricity from wind or solar power, or have a lithium-ion storage facility set up in the basement – making them feel like pioneers in sustainability. Many don’t realize how extremely polluting the production of raw materials from which climate technologies are manufactured really is. Who knew, for example, that 77 tons of carbon dioxide are emitted during the manufacture of one ton of neodymium, a rare earth metal that is used in wind turbines? By comparison: Even the production of a ton of steel only emits around 1.9 tons of CO2.

Almost 50 years after American scientist Donella Meadows and her fellow campaigners warned of “the limits to growth” in their report to the Club of Rome, the overexploitation of nature is taking on a surprising new dimension. The massive demand for materials has continually been the underappreciated factor in all the technologies that are intended to help make the world more sustainable. Wind turbines, photovoltaic systems, electric cars, lithium-ion batteries, high-voltage power lines and fuel cells all have one thing in common: Inconceivable amounts of raw materials are consumed in their production.

In a solar park measuring 1,000 by 1,000 meters, there are fully 11 tons of silver. A single Tesla Model S contains as much lithium as around 10,000 mobile phones. An electric car requires six times as many critical raw materials as a combustion engine – mainly copper, graphite, cobalt and nickel for the battery system. An onshore wind turbine contains around nine times as many of these substances as a gas-fired power plant of comparable capacity.

It is the specific properties they contain that makes these metals so desirable. Cobalt and nickel increase the energy density in a battery. Neodymium amplifies the magnetic forces in wind generators. Platinum accelerates processes in fuel cells, and iridium does the same for electrolyzers. Copper’s conductivity makes it relevant in every electrical installation. Around 150 million tons of copper are installed in power lines around the globe. And humankind is only at the beginning of its energy transition.

According to calculations by the International Energy Agency (IEA), global demand for critical raw materials will quadruple by 2040 – in the case of lithium, demand is expected to be as high as 42 times greater. According to IEA head Fatih Birol, these materials are becoming “essential components of a future clean global energy system.”

Over the course of his professional career, Birol, who has a doctorate in energy economics, has never really had to deal with these materials until recently. His area of focus had always been oil and gas, first as an analyst for OPEC and later, at the IEA, founded in Paris in 1974 by the consuming countries in response to the first oil price crisis. The crisis painfully demonstrated to governments just how dependent they had become on the drip of a few producing states.

Almost a half a century later, Birol is now observing how the industrialized nations are falling into a new dependency – not on oil, but on metals. And it could prove to be even more serious.

Many of these critical commodities come from a small group of countries. Indonesia and the Philippines command around 45 percent of the global nickel supply. China supplies 60 percent of rare earth metals. The Congo is responsible for about two-thirds of cobalt production. South Africa dominates around 70 percent of the platinum market.

The geographical concentration is even more pronounced than in the oil business. OPEC covers just 35 percent of global supply. In mining, on the other hand, only 10 countries produce around 70 percent of the raw materials by value.

The good news is that, from a geological view, there is no shortage of metals. Even the rare earths are neither rare nor earths. Nor are they in any way exclusive to China.

On the other hand, mining is becoming more and more expensive, and ore quality and raw material content are declining. As the tight supply meets surging demand, prices are skyrocketing. Within 12 months, important metals have become massively more expensive: The price of nickel has risen by 26 percent, copper by 43 percent and aluminum by 56 percent. The price of lithium carbonate has roughly tripled in a year to more than $20,000 per ton. At the same time, stocks of metal in warehouses around the world are plummeting.

It’s obvious that something is out of balance. IAE head Birol is familiar with the situation from the oil business, and the metals markets could also fall into a similar situation. Birol speaks of the looming discrepancy between ambition and supply: between the aspiration to protect the climate and the difficulty of obtaining enough affordable copper, nickel and lithium.

Given that the depletion of resources is concentrated in a few countries, particularly those that are politically unstable, their supply is becoming a global security issue. “This could lead to disruptions,” warns Birol.

And it begs the question: How clean are green technologies really?

Spiegel International

Silicon for solar modules, need 45kwh /kg electricity power !this is 3 times the energy consumption of electrolytic aluminum

the most important is,the electricity produced by the way is garbage power!!!!lowquality power.dirty power.

Virtue signalling indeed from Wackernagel! So what if we use 90 million barrels of oil, there are hundreds of years of oil still to be discovered.

“We are using resources of the future to pay for the present.” Has he thought that these resources never leave Earth? Old cars are crushed and the steel is reused to make new ones – there is no problem with resources.

Dr Tim Ball – Historical Climatologist

Book: ‘The Deliberate Corruption of Climate Science’

Book: ‘Human Caused Global Warming, the Biggest Deception in History’

https://www.technocracy.news/dr-tim-ball-on-climate-lies-wrapped-in-deception-smothered-with-delusion/

Clean Energy Exploitations, a nominee for a 2022 Pulitzer Prize.

According to Podcasters Dr. Jay Lehr and Tom Harris of the America Out Loud Podcast Network, the new book, “Clean Energy Exploitations – Helping citizens understand the environmental and humanity abuses that support ‘clean’ energy” is the best written and researched book in years. If there is one book that you read this year, this book is a MUST read.